Waterless Car Washing vs Traditional Methods

Rethinking Vehicle Cleaning in a Water‑Constrained World

Across the automotive, fleet and professional vehicle care sectors, traditional washing methods have remained largely unchanged for decades. Yet the operational and environmental conditions in which these services operate have evolved significantly.

Water availability, wastewater regulation, site restrictions and sustainability expectations now play a central role in how vehicle cleaning operations are assessed – particularly for fleets, commercial sites, retail environments and mobile services.

Conventional wet washing methods typically rely on large volumes of portable water, multiple cleaning stages and dedicated infrastructure to manage runoff and effluent pollution. While effective in removing surface contamination, these systems often introduce secondary challenges related to water consumption, drainage compliance and operational flexibility.

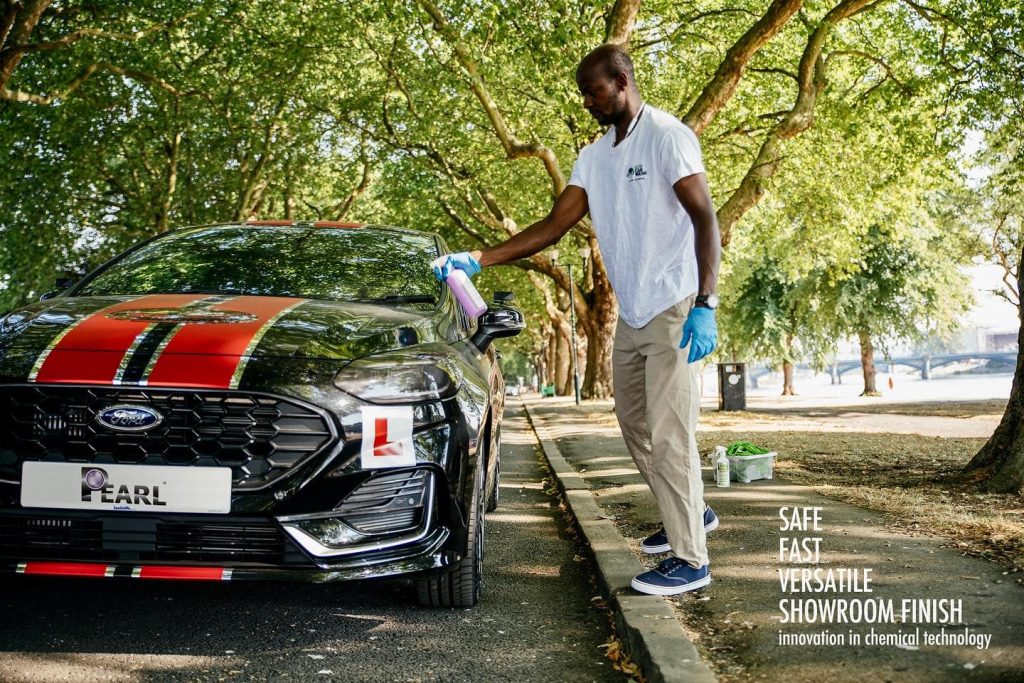

Pearl Waterless car wash technology was developed to address these challenges directly – not by compromising cleaning performance, but by rethinking the process itself.

Rather than washing dirt away with water, advanced waterless formulations are designed to safely lift, encapsulate and remove contamination from vehicle surfaces, while simultaneously cleaning, polishing and protecting in a single controlled workflow.

The comparison below outlines the practical, operational and environmental differences between traditional wet washing approaches and modern waterless car wash systems.

| Feature | Traditional Wet Washing / Valeting | Waterless Car Wash System |

|---|---|---|

| Typical water usage per vehicle | Approximately 150–500 litres per vehicle, depending on method (hosepipe, bucket wash, manual valet or older automatic systems). | No additional water is required during the cleaning process. |

| Process stages | Multi-stage process including pre-rinse, shampoo, rinse, drying, glass cleaning and surface protection. | Simplified from top to bottom, panel-by-panel process: spray, wipe and buff, delivering cleaning, polish and protection in a single workflow. |

| Wastewater and runoff | Generates wastewater and effluent that must be managed in accordance with environmental regulations. | No runoff and no effluent discharge; all contamination is captured within microfibre cloths. |

| Operational locations | Typically restricted to locations with access to water supply, drainage and approved effluent controls. | Suitable for retail parks, shopping centres, indoor environments and multi-storey car parks. |

| Vehicle movement | Vehicles may need to be moved to designated wash bays or drainage-approved areas. | Vehicles can be serviced in situ with no movement required. |

| Equipment and logistics | Often requires hoses, pressure washers, water tanks, power sources and drainage controls. | Minimal equipment is required, enabling highly mobile and flexible operations. |

| Environmental impact | High water consumption with associated energy use and effluent management requirements. | Significantly reduced environmental footprint through zero water use at source. |

What the Comparison Means in Real‑World Operations

The differences highlighted above are not theoretical – they have direct implications for how professional vehicle care operations are delivered daily

For traditional wet washing and valeting, the dependency on water supply, drainage and effluent management typically limits where and how services can be performed. Vehicles often need to be moved to approved wash bays, and operators must account for wastewater handling in line with local environmental regulations.

By contrast, waterless car wash systems remove these constraints. Because no additional water is introduced during the cleaning process and no runoff is generated, vehicles can be serviced in situ, including in locations such as multi‑storey car parks, retail centres, indoor facilities and restricted urban environments.

From an environmental perspective, the elimination of water at the point of use also removes the downstream impacts associated with wastewater treatment, energy consumption and chemical discharge. All contamination is captured mechanically within microfibre cloths, allowing for controlled disposal and a significantly reduced environmental footprint.

Efficiency, Consistency and Scalability

Beyond sustainability, waterless systems also offer operational advantages. By combining cleaning, polishing and surface protection into a single workflow, labour time is reduced and process consistency is improved, an important consideration for fleet operators and professional service providers managing large vehicle volumes.

Minimal equipment requirements further support mobile and scalable operations, enabling services to be deployed quickly across multiple sites without reliance on fixed infrastructure.

For manufacturers, distributors and private‑label partners, these characteristics translate into solutions that are not only environmentally responsible but also commercially viable and adaptable to a wide range of professional use cases.

As regulatory pressure increases and sustainability expectations continue to rise, waterless vehicle care technologies represent a practical evolution in professional cleaning and detailing – one that aligns environmental responsibility with operational efficiency and consistent results.

For organisations evaluating future‑ready vehicle care solutions, understanding these differences is a critical first step.

British manufacturing you can trust, partnering with domestic and international customers to deliver sustainable growth and lasting success.

© Pearl Global Ltd — ISO‑Certified British Manufacturing Excellence in Processes, Systems and Product Quality Standards

All Pearl products are engineered using safe, sustainable, environmentally responsible formulations, designed for professional performance with minimal environmental impact. Manufactured exclusively in the United Kingdom and available worldwide in 25L, 205L and 1000L IBC formats, alongside a full range of premium Nano Ceramic coatings, detailing systems and specialist maintenance solutions.

For product support or commercial trade enquiries, contact: sales@pearlgloballtd.com | +44 (0)845 874 0140

Stay updated — Subscribe to the Pearl Official Newsletter for product releases, ecological insights and global business updates.

Pearl Official Channels & Resources

Pearl FAQ – Your central hub for answers to the most common questions about Pearl products, technologies, manufacturing standards and global distribution.

Pearl Official YouTube – Explore demonstrations, application tutorials, product walk‑throughs and professional detailing techniques.

Pearl Official Instagram – Discover visual highlights, partner showcases, behind‑the‑scenes content and professional detailing results.

Pearl Official Facebook – Follow us for updates, product insights, partner news and global waterless car care innovations.

Pearl Official X – Stay informed with quick updates, industry news, technical insights and global announcements.

Pearl Official Pinterest – Browse collections of eco‑friendly detailing solutions, product features, and inspirational automotive care visuals.